Currently, MTP/MPO fiber optic patch cords have been widely used in high speed rate and high density data center cabling, and their material determines the stability and sustainability of the entire network, so how to identify the quality of MTP/MPO wire? What factors should we consider when choosing MTP/MPO patch cords? This article will provide you with answers one by one.

How to Identify the Quality of MTP/MPO Trunks?

Usually, to get a quality MTP/MPO fiber patch cable, you need to consider various factors, such as the brand of the fiber core, connectors, insertion loss, etc. Below is a list of five characteristics that a high quality MTP/MPO wire should have.

Branded Optical Fiber

MTP/MPO fiber patch cords are usually deployed in small spaces, such as telecom distribution boxes, data center cabinets and so on. In these cases, the fiber core needs to have a bending arc. Poor quality fiber core bends usually result in signal loss, which can lead to interruptions in transmission. However, branded fiber, such as Corning fiber, can greatly improve bending performance, minimize signal loss, and enable faster, more efficient fiber cabling and installation. Therefore, brand name fiber cores are very important for MTP/MPO fiber patch cords.

Industry Standard MTP/MPO Connectors

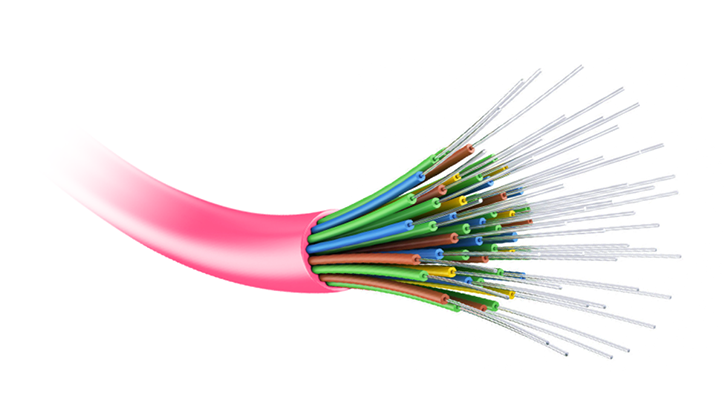

MTP/MPO fiber connectors can package 12, 24 or 72 fibers into a single fiber to increase fiber density, making it popular in data centers where space is limited. Industry-approved MTP/MPO connectors (such as US Conec or Senko connectors) ensure polarity of the MTP/MPO wire, reducing insertion loss and return loss. Industry-standard MTP/MPO connectors are ruggedly constructed and durable enough to be recycled hundreds of times. The interface between the connector and the fiber patch cord is round, so the fiber patch cord can be routed in any direction from the MTP/MPO connector port, simplifying the cabling structure. Therefore, it is also important to purchase superior MTP/MPO fiber optic patch cords with industry approved MTP/MPO connectors.

Insertion Loss

Insertion loss (Insert Loss) is the loss of effective optical power of the link due to the insertion of connectors or plugs. It is one of the key factors affecting the performance of fiber optic network, the smaller the insertion loss, the better the performance of the network. In general, the insertion loss of MTP/MPO multimode fiber patch cable should not exceed 0.6 dB, and the insertion loss of single-mode MTP/MPO fiber patch cable should not exceed 0.75 dB. And for single-mode and multimode MTP/MPO fiber patch cable with low insertion loss (high quality), the insertion loss is usually required to not exceed 0.35 dB. When choosing MTP/MPO fiber patch cable, you can Choose a supplier that provides insertion loss test reports.

Flame Retardant Grade

The housing of MTP/MPO fiber patch cord can be made of different materials with different fire resistance, which can be classified as polyethylene (Polyethylene), polyvinyl chloride (PVC), low smoke and no halogen resistance (LSZH), etc., most of which have good fire resistance properties. If there are higher requirements for the installation environment, such as suspended ceilings and raised floors, it is best to choose MTP/MPO fiber optic patch cords with a higher flame retardant rating, which are less likely to burn or smoke in the event of a fire. The following table lists the common flame retardant grades and application scenarios.

| MTP/MPO National Electrical Code | Flame Retardant Grade | Application Scenarios | Substitutable Grades |

|---|---|---|---|

| OFNP | First class | Horizontal wiring areas and aerated environments | Cannot be replaced by lower grades |

| OFNR | Second class | Vertical cabling areas | OFNP |

| OFNG/OFN | Third class | Common area | OFNP/OFNR |

When buying MTP/MPO fiber optic patch cord, you can directly check its flame retardant rating on the protective jacket, and then choose the right MTP/MPO fiber optic patch cord according to the actual applicable environment of the protective jacket and flame retardant rating of the fiber optic patch cord.

Fiber Optic Patch Cord Testing

MTP/MPO fiber optic patch cord connector end face test: In order to ensure that the fiber optic connector has qualified or higher performance, the International Electrotechnical Commission (IEC) developed IEC 61300-3-35 standard to define the connector end face is qualified.MTP/MPO patch cord connector end face is divided into four areas: fiber core area, cladding area, adhesive edge area and core face. It has requirements for scratches and imperfections in each area inside the connection. Scratches represent permanent linear surface features. Defects include all detectable non-linear features on the fiber, including particles, other debris, pits, chips, edge splinters, etc. The cleaner the end face, the better the quality of the cable. Therefore, to buy the best MTP/MPO cable, you should choose a fiber optic patch cable that passes endface inspection, such as NADDOD MTP/MPO trunks.

| Area | Scratch | Defect |

|---|---|---|

| Fiber core area | No scratch | No defects |

| Cladding area | Not allowed ≥3μm; ≤3μm unrestricted | Not allowed >5μm; 2-5μm 5 places allowed; ≤2μm unrestricted |

| Glue edge area | No limit | No requirement |

| Ferrule surface | No limit | Not allowed ≥10μm |

3D Inspection: The successful connection of a fiber optic line depends on the quality of the fiber, but the quality of this fiber optic patch cord is determined by the size of the end face of the connector itself. If this dimension is not strictly controlled, the network cannot operate reliably for a long time. 3D Inspection defines the parameters of the MTP/MPO fiber optic patch cord connector, as shown below.

| Parameters | Requirement |

|---|---|

| Fiber X angle (SX) | -0.2~0.2° (PC and APC) |

| Fiber Y angle (SY) | ±0.2° |

| Fiber X radius (RX) | ≥2000 mm |

| Fiber Y radius (RY) | ≥5mm |

| Fiber bend radius (RF) | ≥1mm |

| Fiber height (H) | 1000~3000 nm |

| Maximum fiber height difference (HA) | 500 nm |

| Maximum adjacent height difference (HB) | 300 nm |

| Coplanarity | ≤2000 nm |

| Core dip angle | -100nm~+200nm |

If the connector size of MTP/MPO wire does not meet the requirements, problems such as system connection failure will occur. Therefore, it is very important to choose MTP/MPO fiber optic patch cords that pass the 3D interferometer test.

MTP/MPO Fiber Optic Patch Cable Buying Guide

In summary, we need to consider many factors before purchasing MTP/MPO fiber patch cords. Today, many suppliers can provide MTP/MPO fiber patch cords, however, not all of them are quality assured. In order to choose a high quality MTP/MPO fiber optic patch cable, please choose one that meets all the above criteria.

800GBASE-2xSR4 OSFP PAM4 850nm 50m MMF Module

800GBASE-2xSR4 OSFP PAM4 850nm 50m MMF Module- 1How to Choose among Enterprise Switches, Data Center Switches and Home Switches?

- 2Standard PoE Switches and Non-standard PoE Switches

- 3How to Use and Maintain Fiber Optic Patch Cords?

- 4Introduction to Open-source SONiC: A Cost-Efficient and Flexible Choice for Data Center Switching

- 5OFC 2025 Recap: Key Innovations Driving Optical Networking Forward